Introduction: an overlooked industrial stream becomes a lever for impact

In the automotive industry, thousands of extremely robust textile straps are used every year to secure parts on production lines and during internal transport. After a single cycle, these straps are generally considered waste, despite their exceptional technical performance.

Thanks to a tripartite partnership between Volvo Car Gent, Terra+ and Loopipak, this previously invisible stream has become a valorised resource, integrated as high-performance securing straps on reusable pallet packaging intended for industry and logistics.

This collaboration perfectly illustrates Loopipak’s vision:

--> Transform industrial waste into circular, low-tech, robust logistics solutions involving local social enterprises.

This article details this innovative project, its environmental and social implications, and the reasons why the reuse of Volvo straps constitutes a textbook example of successful industrial circularity.

These straps were meant to become waste.

These Volvo straps become Loopipak raw material

Local manufacturing in social enterprises

Loopipak transforms straps and integrates them into its reusable packaging.

1. Terra+: the circularity accelerator that identifies value streams

Terra+ plays a fundamental role in the success of this project. The organisation specialises in identifying, collecting and preparing under-utilised industrial materials. Terra+ detects local reuse opportunities before streams are sent to incineration or low-value recycling.

In this project, Terra+:

- identified the constant stream of textile straps from Volvo’s internal logistics;

- set up a dedicated collection circuit within Volvo’s logistics;

- looked for a company capable of reusing them;

- orchestrated the connection between Loopipak’s industrial needs and the Volvo teams.

--> Without Terra+, this stream would have remained invisible.

With Terra+, it becomes a circular raw material with very high added value.

2. Volvo Car Gent: an industrial site committed to the circular economy

The Volvo Car Gent logistics centre is a reference in sustainable innovation. Keen to reduce its waste footprint, it sought local solutions capable of valorising secondary streams.

This ambition materialised thanks to the direct involvement of Hilde Henderickx and Ruben Van den Branden, the driving forces behind the project:

- opening the site to Terra+ for stream analysis;

- technical collaboration to identify valorisable waste;

- defining with Loopipak the logistical specifications required to transform these straps into industrialisable tools;

- commitment to a reuse model aligned with the environmental strategy of the logistics centre.

--> Volvo is not merely reducing its waste: the company is committing to local circularity, turning its own internal streams into a resource for the regional economy.

3. A unique industrial material: the technical characteristics of Volvo straps

The straps from the Volvo stream have high-quality technical characteristics within the industrial textile market.

Key technical characteristics:

- High mechanical resistance: although not certified, these straps meet Loopipak’s mechanical strength requirements.

- High-density weave: exceptional dimensional stability.

- Low deformation over time, even with repeated reuse.

- Equipped with reusable cam buckles for a complete fastening system.

- Easy to clean without loss of mechanical properties.

--> This quality would have been lost had these straps been incinerated.

--> Reuse therefore offers real technical advantages, not only environmental benefits.

4. Upcycling in sheltered workshops: from raw material to circular product

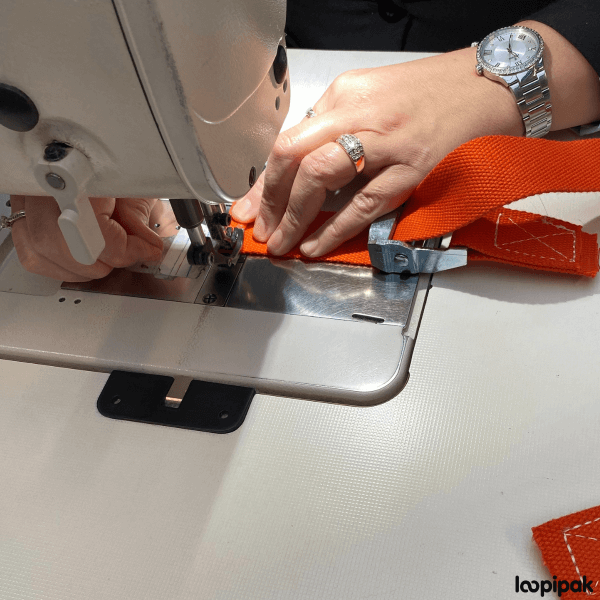

Once collected, the straps are handled by sheltered workshops (ETA). They play a crucial role in:

- cutting the straps to lengths specified in Loopipak’s technical plans;

- assembling buckles and robust fastening systems;

- reinforced stitching;

- individual quality control, essential for a logistics product;

- repairs, which further extend product lifespan.

Loopipak does more than reduce waste:

✔ it creates inclusive employment,

✔ relocates value,

✔ strengthens the social economy,

✔ and demonstrates that circular industry can be social, profitable and high-performing.

5. Proven and measurable logistical performance

The upcycled straps are already in use. They effectively replace:

- new straps.

Common logistical applications:

- securing boxes on pallets;

- fastening reusable pallet covers;

- stabilising loads on trolleys with palletisation bands;

enabling single-person handling of pallet covers.

Benefits observed by users:

- time savings during handling operations thanks to the cam buckle;

- drastic reduction in disposable consumables thanks to Loopipak reusable packaging;

- better standardisation thanks to the recognisable colour.

This product is therefore more than a circular project:

--> it is a proven, high-performance logistical tool.

6. Immediate and significant environmental benefits

Reusing Volvo straps offers a very favourable environmental balance.

1. Waste avoided

Thousands of textile straps, previously destined for incineration, are now reused.

2. Virgin material saved

Each reused strap avoids the production of a new one with a high carbon footprint.

3. Reduced CO₂ emissions

Local transformation combined with numerous reuse cycles greatly reduces associated emissions.

4. Local circularity

The entire cycle takes place within a short radius:

Volvo → ETA → Belgian companies.

This significantly reduces transport-related impacts.

5. Extended lifespan

Repairs included → total circularity.

→ This is high-value circularity, far more effective than simple recycling.

7. Turning waste into a resource: a replicable industrial model

The reuse of Volvo straps by Loopipak is a model that can be replicated across many industries.

This project demonstrates that:

- companies generate under-exploited material streams with remarkable technical qualities;

- local circularity can create products that perform better than newly purchased ones;

- the circular economy can be social, through the involvement of social enterprises.

This success paves the way for similar partnerships where industry becomes a supplier of circular raw material.

Conclusion: an exemplary partnership and a new standard for sustainable logistics

Thanks to Terra+, Volvo Car Gent and the sheltered workshops, Loopipak has transformed an industrial waste stream into a sustainable, high-performance and economically efficient logistics solution.

The Volvo straps are no longer a residue:

→ they are professional, reusable, reused, repairable and circular products.

Ce projet incarne la This project embodies Loopipak’s mission:mission de Loopipak :

→ reduce single-use, valorise industrial waste streams, and create measurable environmental and social impact.

→ Vous souhaitez rev→ Would you like to valorise an industrial waste stream? aloriser un flux de déchets industriels ?

→ Are you looking for reusable logistics solutions?

Volvo straps: how Loopipak turns them into a circular logistics solution