1. Objectives

bpost is launching an ambitious pilot project centered around a reusable laundry bag, designed to:

- Simplify and streamline internal flows,

- Test the concept of reuse on a large scale,

- Explore how it could be extended to other companies and services within the sector.

75 bags have been put into circulation. Initial feedback is expected in the coming weeks, but enthusiasm for the project is already strong.

2. Collaboration

This bag was co-developed with a highly motivated, dynamic team at bpost, committed to finding concrete solutions to reduce waste. Together, we followed a step-by-step approach:

- Two prototypes were created,

- Adjustments were made to:

- the handle placement for optimal grip,

- the shape and dimensions of the bag,

- the location of the sewn-in label holder,

- the designated area for the shipping label sticker,

- A unique datamatrix was developed to allow automated scanning,

- Tests were carried out on the bpost sorting line to validate compatibility with existing infrastructure.

3. Result

The outcome of this collaboration is a cubic bag that is lightweight, washable, and durable — designed for intensive and repeated use. It includes an integrated label holder and is made from repurposed materials, in full alignment with Loopipak’s core values.

Most importantly, the bag is not only repairable but will also be repaired when needed to extend its lifespan.

Custom Technical Features:

- Dimensions : 50 x 40 x 30 cm

- Rigid base: made from repurposed polypropylene panel

- Zipper closure: runs along 3 sides of the top panel for wide opening and easy access

- Handle: sewn along 3 sides for better grip and compatibility with bpost’s sorting line

- Color: white, with an outer surface made from reused PVC material

- Label window: made from reused material, located on the front of the bag, fits a 10.5 x 15.0 cm paper label, secured with a small Velcro closure

- Shipping label zone: a 15 x 20 cm sewn fabric area to attach removable shipping stickers

- Datamatrix: two unique codes applied externally to enable automated scanning and tracking in logistics flows

- Reuse info and return address: affixed directly to the bag to ensure traceability and proper reintegration

Clear Signage

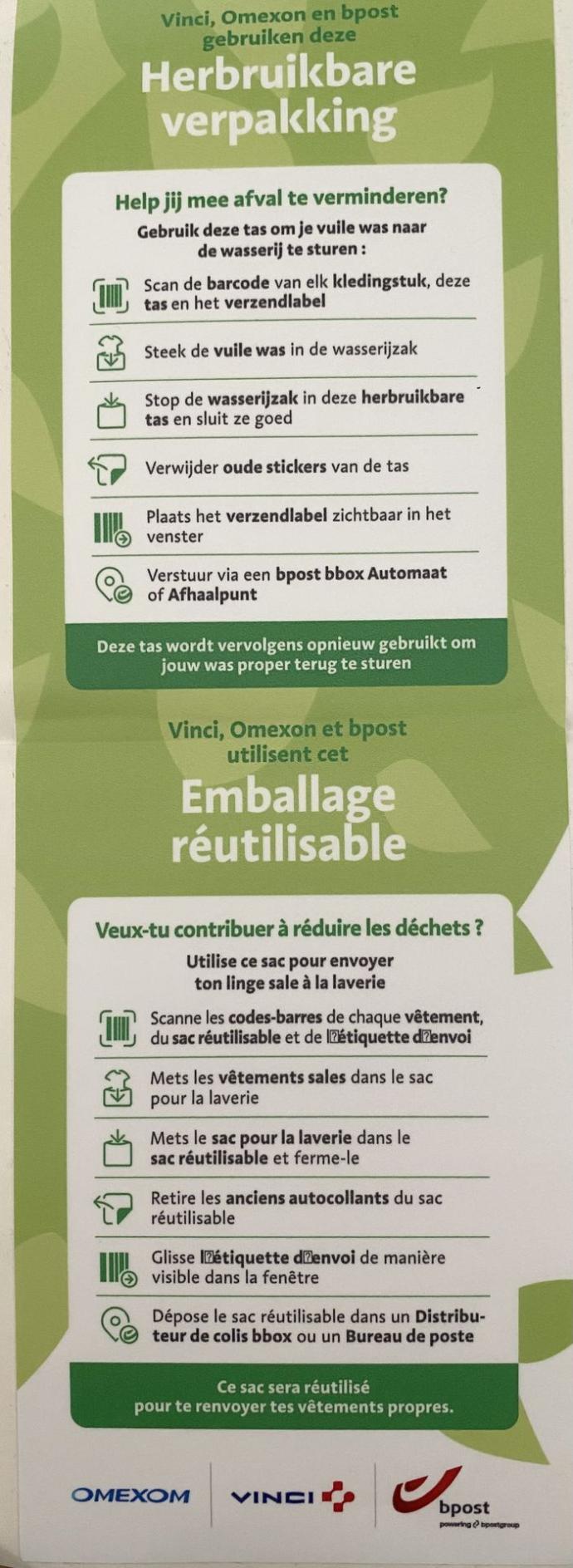

The project also includes specific work on signage — essential to ensure proper adoption and correct use by teams.

Two key stickers are used:

- “If you find me”: to prevent loss,

- Clear instructions on how to use the bag for sending dirty laundry to the laundry facility.

This approach aims to actively guide users — a key success factor in any reusable packaging project. Without clear instructions and user engagement, reusable packaging can easily be misused, lost, or forgotten.

Why bpost chose to work with Loopipak

bpost selected Loopipak for several reasons:

- Our expertise in reuse and repair,

- Our ability to work with repurposed materials,

- Our production in adapted work enterprises (social enterprises),

- Our responsiveness, flexibility, and scalable production capacity,

- Our tailored approach and rigorous project follow-up,

- And, of course, our commitment to deadlines and reliability.

This project proves that textile logistics too can be reinvented without single-use plastic — a great example of sustainable, practical, and replicable collaboration!

A Laundry Bag for bpost: The Start of a Promising Pilot